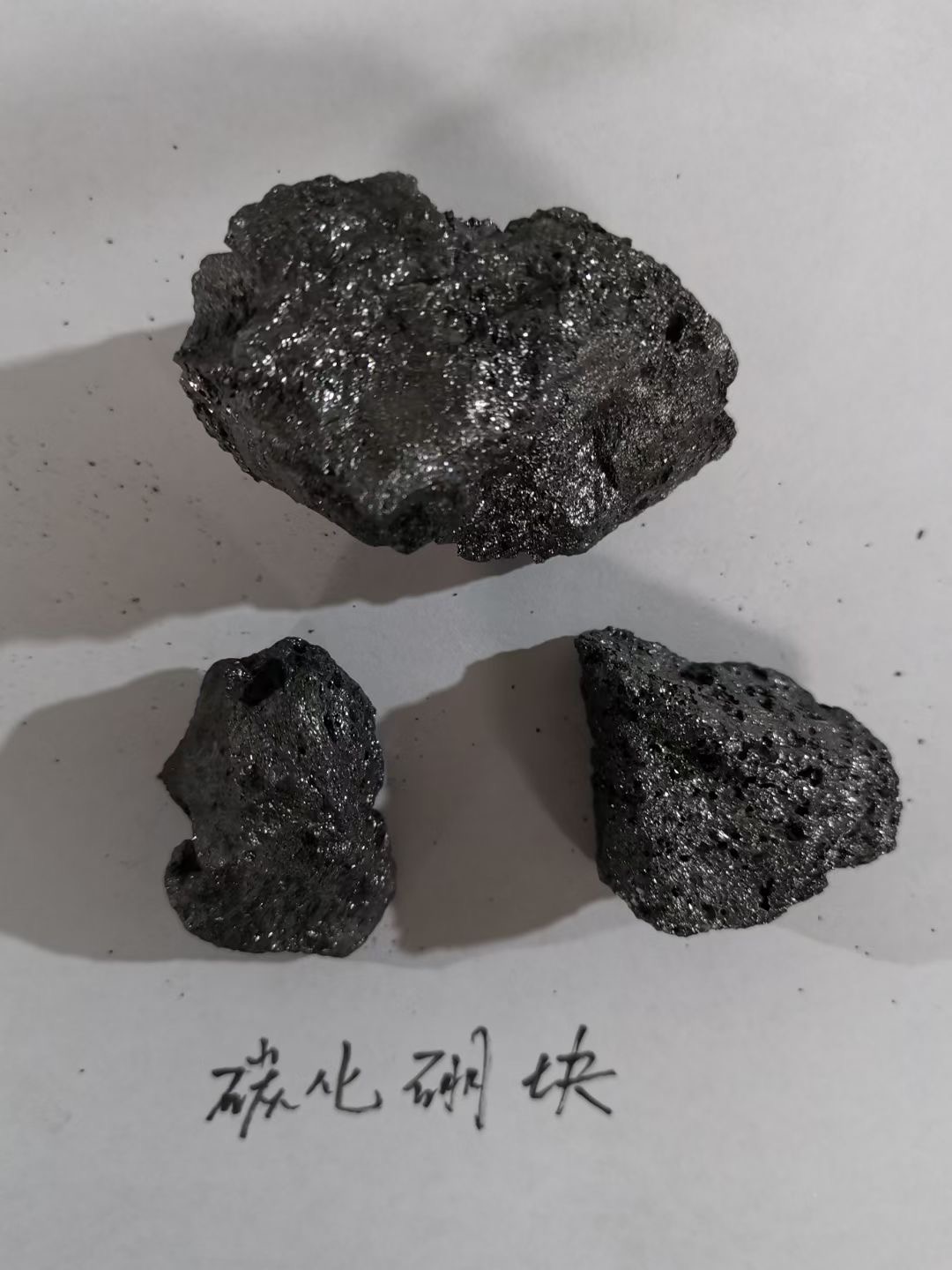

Boron Carbide B4C is produced by high temperature smelting boric aid and carbon materails in electric furnaces.

Boron Carbide B4C have high temperature resistance,acid and alkali resistance,high strengh,good chemical stability,and low specific weight,so Boron Carbide B4C is widely used in many new materials fields.

| Grit Size | Size(μm) | Chemical Composition | |||

| B% | C% | Fe2O3% | BC% | ||

| 60# | 315-215 | 78-81 | 17-22 | 0.2-0.4 | 97-99 |

| 80# | 200-160 | ||||

| 100# | 160-125 | ||||

| 120# | 125-100 | 78-80 | 17-22 | 0.2-0.4 | 96-98 |

| 150# | 100-80 | ||||

| 180# | 80-63 | ||||

| 240# | 60-50 | 77-80 | 17-22 | 0.3-0.5 | 96-97 |

| 280# | 50-40 | ||||

| 320# | 40-28 | ||||

| W40(360#) | 35-28 | 76-79 | 17-21 | 0.3-0.6 | 95-97 |

| W28(400#) | 28-20 | ||||

| W20(500#) | 20-14 | 75-79 | 17-21 | 0.4-0.8 | 94-96 |

| W14(600#) | 14-10 | ||||

| W10(800#) | 10-7 | 74-78 | 17-21 | 0.4-0.9 | 92-94 |

| W7(1000#) | 7-5 | ||||

| W5(1200#) | 5-3.5 | 74-78 | 17-21 | 0.5-0.9 | 90-93 |

| W3.5(1500#) | 3.5-2.5 | ||||

| -325# | <45 | 74-79 | 17-22 | <0.4 | 92-97 |

| 0-44μm | <45 | ||||

| -200# | <90 | 74-80 | 17-22 | <0.3 | 94-97 |

| -100# | <150 | ||||

| -25μm | <25 | 74-79 | 17-21 | <0.3 | 92-96 |

| -10μm | <10 | 74-78 | 17-21 | <0.3 | 91-95 |

| 60#-150# | 250-75 | 77-81 | 17-22 | <0.3 | 95-98 |

| 40#-120# | 315-106 | ||||

| 30#-60# | 355-250 | ||||

| Boron carbide | 355-250 | 92-80 | 17-23 | <0.3 | 90-99 |